Behind the Counter, Ahead of the Curve: The Rise of AI-Driven Restaurant Operations

In a world where razor-thin margins meet sky-high customer expectations, restaurants are under constant pressure to deliver more: more consistency, more speed, more sustainability with less: less waste, less downtime, and less manual errors. In this world, traditional operating models fall short and need re-invented.

Welcome to the era of intelligent restaurants, where the use of Artificial Intelligence (AI) and the Internet of Things (IoT) or AIoT, is quietly transforming operations from being reactive to proactive. Sensors monitor equipment activity, algorithms predict failures, and dashboards offer real time insights — not just data. It’s not about automation alone; it’s about operational transformation.

Forward-thinking operators are already reaping the benefits: lower utility bills, extended equipment lifespans, reduced food waste, better occupant comfort and kitchens that practically operate autonomously. Beyond these advantages, technologies are also helping restaurants meet rising expectations for good customer service, regulatory compliance, and corporate sustainability goals.

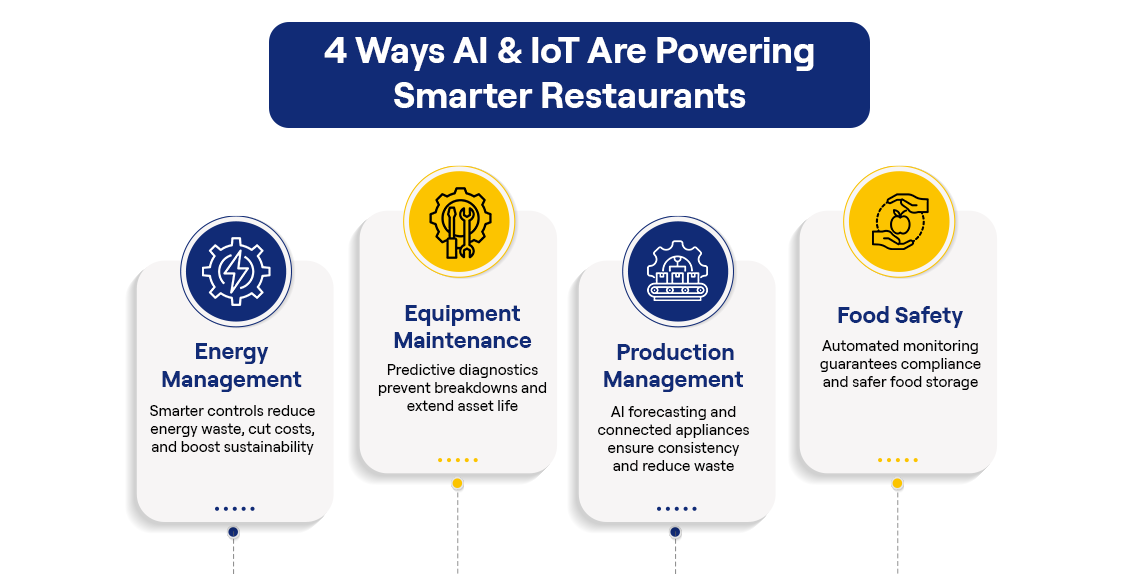

This article breaks down how smart technologies are being applied across four critical areas of restaurant operations: energy management, equipment maintenance, production management, and food safety, and what that means for the kitchens of tomorrow.

Energy Management: Precision for Every Kilowatt

Restaurants are among the most energy-intensive commercial spaces. According to US EPA, Energy Star data, restaurants, especially quick service restaurants, use 10x the energy of regular commercial buildings1. Inefficient HVAC, lighting, and kitchen appliances can quietly drain profit margins. With real time monitoring and AIoT-driven automation, energy management is becoming smarter, more granular, and proactive.

Enhancements

- Multi-Tiered Dashboards deliver both enterprise-wide visibility and localized, role-specific insights.

- Asset Performance Dashboards track how efficiently each piece of equipment runs; flagging underperformers early.

- Energy Use Intensity (EUI) Analysis compares performances across stores and highlights hidden savings opportunities.

- AI-Driven Demand Control automates load shedding during peak hours to avoid spikes and penalties.

- Daylight Harvesting & Ventilation Tuning fine-tune environmental settings to match natural light and kitchen activity, reducing waste without compromising comfort.

- Occupancy-Based Controls & Remote Equipment Scheduling automate HVAC and food preparation equipment settings based on foot traffic and store hours.

Benefits

These technologies are turning energy management into a strategic advantage, helping streamline workflows, reduce manual oversight, and support smarter, more responsive kitchen environments.

- Lower utility costs and reduced wear on equipment

- Real-time adjustments reduce energy waste

- Contribution to sustainability goals and compliance

Example

A QSR chain rolled out an energy management program across its locations, using AI-powered analytics to monitor equipment and optimize performance. The initiative led to saving more than 15% in energy consumption 2. (Note: estimated based on reported project results; actual outcomes may vary.)

Equipment Maintenance: From Break-Fix to Predictive

Downtime in a kitchen is costly, not just in repairs, but in lost revenue and service disruption. AI-enabled diagnostics are shifting maintenance from reactive to predictive, increasing uptime and cutting service costs.

Enhancements

- Predictive-Based Maintenance eliminates guesswork, triggering service only when needed.

- Oil Life Monitoring maintains food quality while minimizing fryer oil waste.

- Digital PM Logs automate preventive maintenance tracking, ensuring compliance and eliminating manual errors.

- Remote Malfunction Resolution reduces downtime with faster diagnostics and fewer technician visits.

- Smart Scheduling aligns maintenance with off-peak hours to reduce disruption.

Benefits

Maintenance is evolving into a data-driven, predictive process that improves reliability, minimizes disruptions, and frees up staff to focus on other aspects of the business’s operations rather than urgent fixes.

- Increased uptime and kitchen reliability

- Lower maintenance costs and extended asset lifespans

- Streamlined compliance and operational efficiency

Example

Across the foodservice and food processing industries, operators implementing AI-driven predictive maintenance systems report striking improvements in equipment reliability. Many organizations have seen 20–30% reductions in maintenance costs and 15–25% drops3 in unplanned downtime. These gains stem from real-time diagnostics, usage-based maintenance & repairs, and automated maintenance tracking — shifting teams from reactive repairs to proactive operations. This transition not only boosts equipment uptime and lifespan but also gives staff more bandwidth to focus on delivering great customer service.

Production Management: Consistency at Scale

Maintaining consistency across multiple locations is one of the toughest challenges in the foodservice industry. Smart production systems help maintain quality and predict demand, without increasing manual effort.

Enhancements

- Remote Menu Pushes allow centralized updates across all stores, ideal for promotions, policy changes, or nutritional compliance.

- Cook Cycle Monitoring ensures optimal cooking times, quantities and conditions.

- IoT-Controlled Appliances standardize cooking across locations by enabling remote settings, that can be uniformly applied, for temperature and timing.

- AI Demand Forecasting predicts footfall, enabling stores to preheat and prep just the right amount of food.

Benefits

Intelligent production tools enable consistent output across locations, reduce operational stress on teams, and ensure the brand promise is delivered with every order.

- Consistent food quality and presentation

- Reduced food waste and ingredient spoilage

- Enhanced productivity and less human error

Example

A large restaurant chain implemented a connected kitchen program to monitor cold storage across their locations. By leveraging real time data from walk-in chillers, the chain achieved a 20-25%4 improvement in temperature compliance—ensuring ingredients were stored at optimal conditions, reducing spoilage, and preserving food quality across all locations. (Note: based on reported outcomes from multi-site implementations; actual results may vary.)

Food Safety Management: Automated Compliance, Assured Trust

Food safety is most important, but manual tracking of temperature logs, foodborne illness incidents, and cleaning/ sanitation practices is time-intensive and error-prone. Smart sensors and alerts provide 24/7 monitoring and peace of mind.

Enhancements

- HACCP Alerts notify staff of any deviations from food safety protocols in real time.

- Refrigeration & Door Monitoring ensure stable temperatures and flags fluctuations.

- Defrost Cycle Automation improve energy efficiency without compromising food safety.

Benefits

Food safety is shifting from manual checks to automated assurance — helping teams stay audit-ready, reducing food spoilage, and maintaining high standards with less effort.

- Reduced food waste

- Improved audit readiness and regulation compliance

- Decreased manual work for managers and staff

Example

A restaurant chain implemented a connected program with IoT-enabled monitoring to improve food safety and compliance. With predictive insights and automated alerts, they maintained cold room temperature compliance at 91%, supporting HACCP5 goals by reducing manual checks, preventing spoilage, and ensuring safer food storage conditions5.

A Unified Vision for the Smart Restaurant

What do all these systems have in common? They speak to a larger truth: the future of restaurant operations is data-driven, automated, and intelligent. By investing in IoT and AI technologies, operators aren’t just cutting costs, they’re building smarter, safer, and more sustainable restaurants. These investments will soon be table stakes when operating such businesses.

The payoff isn’t just in numbers. It’s in better customer experience, happier staff, and a resilient operation that’s ready for whatever comes next.

SEPTEMBER

2025

Author

Parminder Singh, Director, Presales & Offering Management for Americas, Carrier Abound

Parminder Singh leads Presales & Offering Management for Americas at Carrier Abound in North America and is primarily focused on crafting innovative and award-winning energy management and IoT enabled solutions for multi-site operators. He has over 20 years of experience working in product management, solution design, client engagement, operations management, business consulting, new product development, launch and global delivery. He holds a graduate degree in Mechanical Engineering and is a post-graduate in Business Administration.

References

1Energy Star for Small Business: Restaurants

2Case Study: A Large Franchisee of a Pizza Restaurant Chain Takes a Slice Out of Energy Consumption

3Implementing an AI-Driven Predictive Maintenance System for Food Processing Equipment

4Case Study: A Large Food Service Company Transformed the Restaurant Operations of its Pizza Chain

5Case Study: The Connected Restaurant Program Digitally Transformed Operations at Over 150 KFC Restaurants of Sapphire Foods