How IoT is Making QSR Operations Connected & Efficient

In today’s food service industry, intelligent operations are redefining what it means to be a modern restaurant. It’s no longer just about ambiance or great food or digital experiences in the stores — it’s also about how efficiently a restaurant runs behind the scenes. Speed still matters, especially in Quick Service Restaurants (QSRs), but speed alone isn’t enough. Today, QSR operations need to be powered by smart technologies so as to deliver a great experience consistently and efficiently.

The rising need for visibility, predictability of operations, and data-backed decision-making is also driving technology adoption. Decisions are made in advance to enable smooth operations and prevent issues from arising. Manual data logging and managing cand track performance easily. There’s a shift of focus to become more proactive.

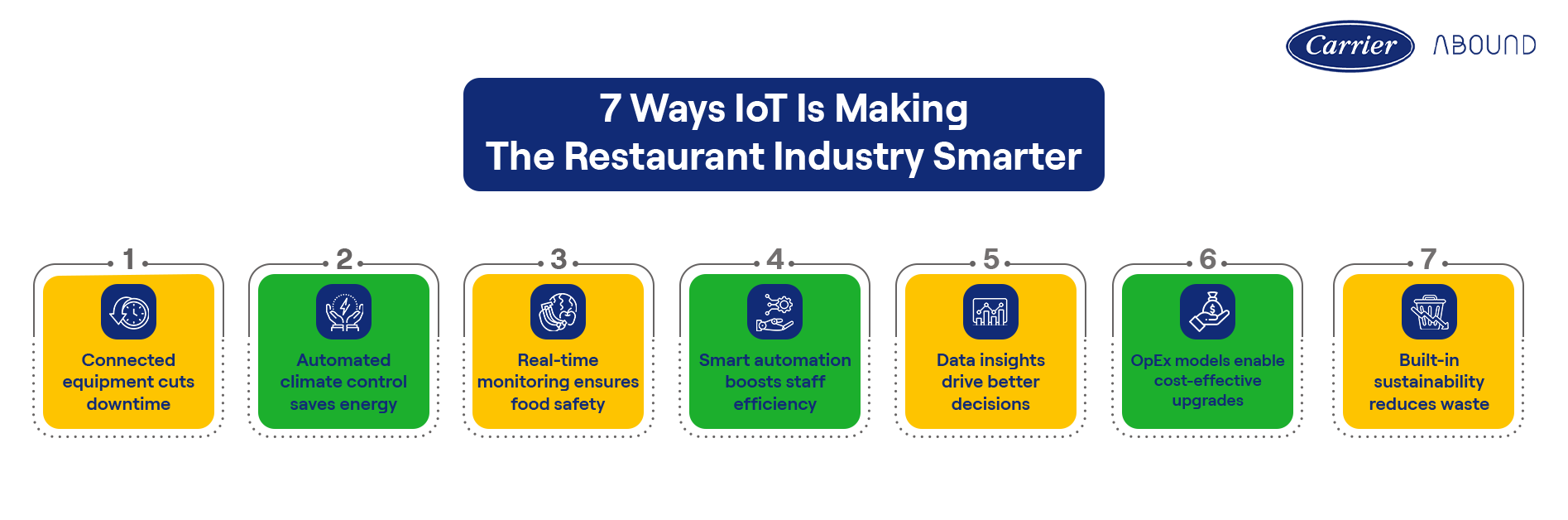

At first glance, this shift might seem dramatic. But in practice, it’s a natural evolution of how restaurant buildings and kitchens operate. The real innovation lies in how the Internet of Things (IoT) enables equipment, systems, and sensors to communicate and automate actions — creating an intelligent loop that keeps operations running smoothly.

This level of intelligence is especially critical in the fast-moving QSR environment, where even seconds can impact service quality and customer satisfaction. By embracing IoT-enabled restaurant systems, operators gain actionable insights, lower operating costs and minimize downtime.

In this blog, we explore <a href="https://abound.carrier.com/en/worldwide/media-resources/archive/key-components-for-restaurant-operations-through-iot-and-ai-solutions/">how IoT is transforming restaurant operations</a> — and how this shift is unlocking measurable gains in performance, reliability, and customer experience.

1. From Silent Machines to Active Data Hubs

In QSRs, equipment like HVAC systems, refrigerators, ovens, fryers, makelines and beverage machines form the backbone of daily operations. Traditionally, these pieces of equipment operated in isolation and required manual monitoring. Today, with IoT, they are digitally connected — constantly generating data that enables real-time monitoring and performance analysis.

This connectivity allows operators to shift from reacting to issues to proactively solving them, before they snowball into bigger problems. The data can be sent for analysis by Artificial Intelligence tools, to predict issues and recommend corrective actions. Think of it this way: the system detects when a freezer’s temperature exceeds the safe limit—before it compromises food quality. It automatically flags the issue and recommends a check-up or tuning of the unit’s temperature controls. Or consider early signs of oven wear, identified before it leads to a midday breakdown. These insights aren’t just helpful — they’re transformative.

With real-time visibility into equipment operations and performance, QSR operators can pinpoint inefficiencies and address issues before they escalate. This not only reduces unplanned downtime and repair costs but also extends the life of the equipment.

For large-scale QSR networks, this shift is game-changing. When your machines can “talk,” you move from guesswork to precision—managing operations smarter, faster, and with fewer disruptions.

2. Smarter Spaces: Climate Control That Thinks for Itself

Modern QSRs have best-in-class kitchens, enabling processes to be completed as per design. Given that this is where the staff work their magic to deliver the food promised by the brand, energy management and environmental control have become central to both the bottom line and to keeping the staff comfortable. With IoT, building management systems (BMS) are no longer restricted to fixed schedules or static settings. Instead, they can be enhanced to automate actions that respond dynamically to foot traffic, kitchen load, weather changes, and utility demand spikes. Let’s break it down:

- A hot summer day with a packed back and front-of-house? The HVAC system ramps up cooling.

- Off-peak hours with minimal occupancy? Systems scale down to conserve energy.

- Griddle temperatures rising during the lunch rush? Airflow adjusts automatically to maintain thermal comfort - no manual tweaks required.

The result? Energy efficiency, employee comfort, and guest satisfaction - all achieved autonomously. Smart buildings, powered by IoT, are now foundational to high-performing QSR portfolios.

3. Digitized Food Safety: From Checklists to Certainty

In QSR operations, food safety compliance is both a regulatory requirement and a critical business risk factor. With IoT-enabled sensors embedded in refrigerators, prep stations, and holding cabinets, restaurants can automate Hazard Analysis and Critical Control Points (HACCP) logging. No more scribbled clipboard logs or guesswork.

Here's what that looks like in practice:

- Real-time temperature logs synced to the cloud

- Threshold-based alerts when deviations occur

- Historical data instantly available for audits or recalls

- Accountability is built into every process

This not only reduces human error, but it also ensures traceability - a critical advantage in managing foodborne illness risks or supplier disputes. In tightly regulated markets, this can be a brand’s reputation-saving tool. For operators, this means shifting from checklists to certainty: less manual work, more consistency, and clear, traceable records.

4. Intelligent Automation: Beyond the Kitchen

Automation is often associated with robotics or AI. But in the QSR industry, automation powered by IoT is more subtle—and arguably more impactful.

Consider these day-to-day realities:

- Refrigeration units that self-report temperature fluctuations or maintenance needs

- HVAC sensors that alert teams when service is needed, enhancing guest comfort without extra labor

- Temperature monitoring in the makeline, freezers, and walk-in coolers (WIC) that ensures food stays within safety thresholds, reducing compliance risk and potential spoilage

These aren’t moonshot ideas—they’re already being deployed by forward-thinking QSR brands

This shift enables leaner facility teams to manage more locations with fewer disruptions and better outcomes. It also frees up in-store staff to focus on what matters most: delivering a consistent, high-quality experience to every customer, every time.

5.Turning Data into Decisions: The IoT Advantage

The real power of IoT is in the data that gets generated and what that data enables. Traditionally, data related to energy, maintenance, and food safety was often siloed, if captured at all. QSR store managers and central facility managers relied on gut instinct and historical performance. With IoT, every interaction, whether it’s a fryer cycle or a compressor restart becomes a data point.

Aggregate that across hundreds of stores, and suddenly you unlock:

- Asset performance benchmarks

- Energy consumption trends

- Store-level anomalies and best practices

- Predictive maintenance alerts

- Staff compliance data for SOPs

This isn’t just about cost control. It’s about transforming invisible variables into measurable, actionable KPIs. For enterprise-level QSR operators, it means building smarter portfolios, where decisions about equipment upgrades, layout changes, vendor selections and even menu offerings are driven by data, not guesswork.

6. The OpEx Edge: Smarter Investment, Faster Returns

Conventionally, outfitting a restaurant required significant upfront investments in equipment and controls. Through IoT-enabled ecosystems, we’re seeing a shift - from capital expenditure (CapEx) to operating expenditure(OpEx). Here’s how:

- Sensors and platforms can often be retrofitted to existing infrastructure.

- Subscription-based models make advanced analytics and monitoring more accessible.

- Cloud-based platforms eliminate the need for heavy IT infrastructure.

- Multi-location views enable centralized oversight - even without on-site expertise.

OpEx models align with the broader trend in enterprise technology, where flexibility, scalability, and rapid deployment are more valuable than ownership. For the QSR industry, this shift enables smarter spending, quicker adoption, faster ROI, and lower risk when upgrading systems across franchises or corporate-owned locations.

7. Sustainability Built In: A Smarter, Greener Future

Sustainability was once seen as a trade-off. In the race to serve food fast, environmental performance was often sidelined. IoT flips that script. By optimizing energy use, reducing waste, and extending equipment lifespan, IoT-enabled systems drive operational sustainability by default, not as a bonus, but as a built-in benefit.

For instance:

- HVAC optimization reduces emissions without compromising comfort

- Improved tracking of food prep and holding processes cuts down waste and ensures consistent freshness.

- Equipment lasts longer, avoiding premature replacement, and saving both material and money

- Data helps QSR brands set, measure, and report ESG goals with confidence

Let’s not forget sustainability is slowly becoming a competitive differentiator. Customers and franchise investors now view operational integrity and environmental responsibility as an key element of brand value. In that light, IoT isn’t just making restaurants smarter; it’s making them future-ready.

Final Thoughts: A Connected Future

In the world of Quick Service Restaurants, every minute matters. But behind the scenes, it's no longer just instinct driving decisions — it’s intelligent systems, powered by IoT, working quietly and efficiently. This silent layer of innovation is reshaping the industry, enabling operators to focus on what truly counts: quality, speed, and consistency.

So, while the customer sees a clean space and a warm meal, or even a cold salad, delivered fast, what they don’t see is the complex IoT-driven systems keeping that promise intact, in every store, everyday. In an industry where margins are tight, labor is stretched, and consistency is everything, IoT is now the new foundation for success.

AUG